News Center

How Much Does a Laser Cutting Machine Cost?

The price of a laser cutting machine varies significantly based on type, power, and functionality. Generally:

- Fiber laser cutters: 10,000𝑡𝑜10,000to500,000+

- CO₂ laser cutters: 8,000𝑡𝑜8,000to200,000+

- Small desktop/DIY laser cutters: 500𝑡𝑜500to10,000

The final cost depends on power, brand, automation level, and customization needs.

Laser Cutting Machine Types & Their Applications & Costs

Different types of laser cutters serve different industrial needs, with prices varying accordingly.

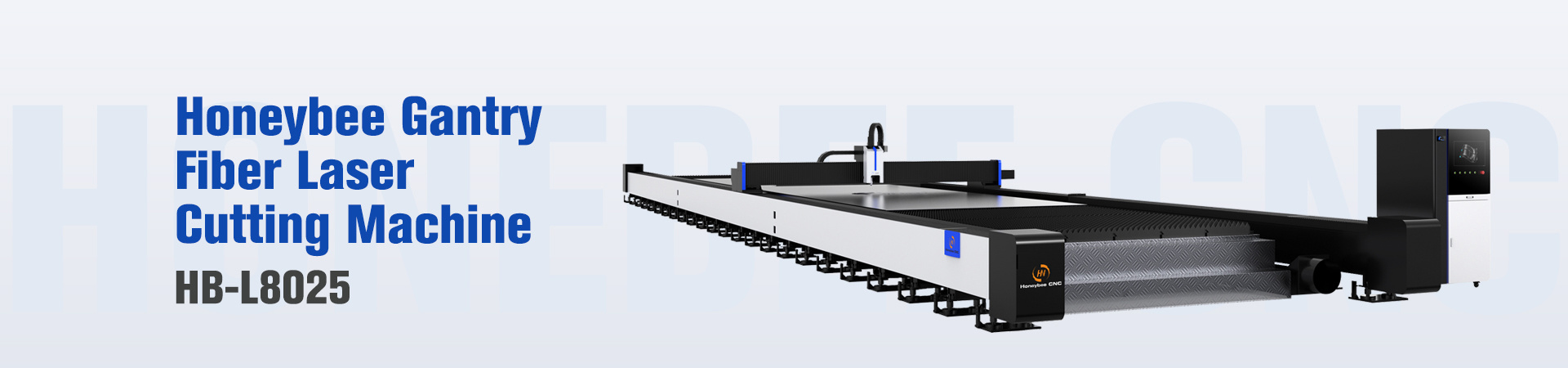

1. Fiber Laser Cutting Machines

✅ Best for: Metal cutting (steel, stainless steel, aluminum, copper)

✅ Advantages: High precision, fast speed, low maintenance

✅ Typical Price Range (Steel):

- 500W: 15,000−15,000−25,000 (1-3mm mild steel)

- 1,000W: 30,000−30,000−60,000 (1-6mm mild steel)

- 6,000W+: $200,000+ (industrial-grade cutting, up to 25mm steel)

2. CO₂ Laser Cutting Machines

✅ Best for: Non-metal materials (acrylic, wood, leather, plastics)

✅ Advantages: Smooth cuts, lower initial cost than fiber lasers

✅ Typical Price Range:

- 60W-100W: 8,000−8,000−30,000 (engraving, thin material cutting)

- 150W-300W: 30,000−30,000−100,000 (thicker plastics, wood, rubber)

3. Desktop/Small Laser Cutters

✅ Best for: DIY, small businesses, engraving

✅ Advantages: Compact, affordable, easy to use

✅ Typical Price Range:

- Diode Laser (10W-20W): 300−300−2,000 (engraving)

- CO₂ (40W-80W): 3,000−3,000−10,000 (cutting thin materials)

Market Price Fluctuations: What Affects the Cost?

Several factors influence laser cutter prices:

- Laser Power (Wattage) – Higher power = higher price (e.g., 500W vs. 6,000W).

- Machine Size & Work Area – Larger cutting beds increase costs.

- Automation Level – Manual vs. CNC vs. robotic loading systems.

- Brand & Country of Origin – European/German machines (e.g., Trumpf, Bystronic) are more expensive than Chinese-made machines.

- Technology & Features – AI-assisted cutting, autofocus, and cooling systems add cost.

Beware of Extremely Low Prices: Why Cheap Machines Fail

- Low-quality laser tubes (CO₂) or fiber modules – Short lifespan, unstable power output.

- Poor structural materials – Weak frames affect precision and durability.

- Lack of safety features – Increasing fire & operation risks.

- No after-sales support – Difficult to repair when issues arise.

Key Rule: If the price seems too good to be true, it likely is.

How to Choose the Right Laser Cutting Machine?

Before purchasing, consider these factors to avoid buying an unsuitable machine:

1. Supplier Qualifications & Reputation

✅ Check if the manufacturer has:

- ISO 9001 certification

- CE, FDA, or other industry-standard certifications

- Customer reviews & case studies

❌ Avoid unknown brands with no history of production or support.

2. Customization Capabilities

Can the supplier adjust the machine to your needs? (e.g., larger worktable, automation features)

3. After-Sales Service & Warranty

✅ Good suppliers provide:

- On-site training

- Technical support & spare parts availability

- Warranty (at least 1-2 years for laser sources)

❌ Avoid suppliers with no local support or slow response times.

Final Thoughts: Invest Wisely in the Right Machine

Laser cutting machines vary widely in price depending on type, power, and manufacturer quality. While fiber lasers dominate metal cutting, CO₂ lasers remain preferred for non-metal materials, and small desktop lasers fit hobbyists & small businesses.

Key Takeaways:

✔ Define your cutting needs (material, thickness, precision).

✔ Compare brands & technical support rather than just price.

✔ Avoid ultra-cheap machines—quality issues lead to costly downtime.