News Center

What Is a Fiber Laser Cutting Machine? How Does It Work?

Introduction to Fiber Laser Cutting Machines

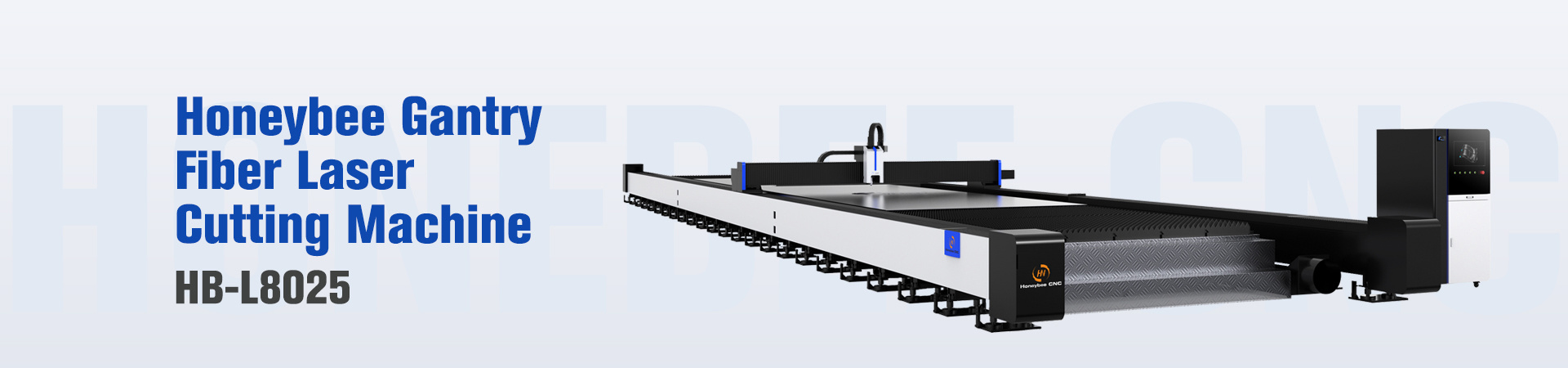

Fiber laser cutting machines represent the pinnacle of precision and efficiency in modern metal fabrication. They use a focused beam of light from a fiber laser to melt, burn, or vaporize materials, resulting in clean, accurate cuts. At Dalian Honey Machinery Co., Ltd., our HoneybeeCNC fiber laser cutting machines are engineered to deliver top-tier performance across various industries, including shipbuilding, mining, and engineering machinery.

The Science Behind Fiber Laser Cutting: How Does It Work?

The core of a fiber laser cutting machine’s operation involves several key stages:

- Laser Generation: A fiber laser source, typically doped with elements like Ytterbium, generates a high-intensity light beam.

- Beam Transmission: The laser beam is channeled through fiber optic cables, ensuring minimal energy loss during transmission.

- Focusing: A focusing lens concentrates the laser to an extremely small, high-energy spot on the material surface.

- Cutting Process: The focused laser beam rapidly heats the material to its vaporization point. Simultaneously, a coaxial assist gas (such as oxygen, nitrogen, or argon) is used to expel molten material and protect the lens from debris.

Troubleshooting Common Issues in Fiber Laser Cutting

Even with advanced technology, some challenges can arise during fiber laser cutting. Here's a look at common problems and effective solutions:

1. Incomplete Cutting (Not Cutting Through)

Causes:

- Insufficient Laser Power: The laser's power output is not high enough for the material's thickness or composition.

- Incorrect Focus Setting: The laser beam is not focused correctly on the material's surface.

- Inadequate Assist Gas Pressure/Type: Insufficient pressure or the wrong type of assist gas can hinder the removal of molten material.

- Cutting Speed Too High: The laser is moving too quickly to effectively cut through the material.

Solutions:

- Increase Laser Power: Adjust the laser's power level based on the material's thickness and type.

- Adjust Focus Position: Fine-tune the focus to ensure the laser beam is precisely concentrated on the material's surface.

- Optimize Assist Gas: Verify the correct type and pressure of assist gas for the material. Oxygen is typically used for mild steel, while nitrogen or argon are used for stainless steel and aluminum.

- Reduce Cutting Speed: Lower the cutting speed to allow the laser to effectively penetrate the material.

2. Dross Formation (Burrs on Cut Edges)

Causes:

- Low Cutting Speed: The laser lingers too long, causing excessive heat buildup and dross formation.

- Incorrect Assist Gas Pressure: Too low or too high pressure can lead to dross.

- Contaminated Material Surface: Dirt, oil, or rust on the material can interfere with the cutting process.

Solutions:

- Increase Cutting Speed: Optimize the cutting speed to balance precision and minimize heat buildup.

- Adjust Assist Gas Pressure: Experiment with different assist gas pressures to find the optimal setting for clean cuts.

- Clean Material Surface: Ensure the material is clean and free of contaminants before cutting.

3. Warping or Thermal Distortion

Causes:

- Excessive Heat Input: High laser power or slow cutting speeds can cause the material to overheat and warp.

- Thin Material: Thinner materials are more susceptible to thermal distortion.

Solutions:

- Reduce Laser Power: Lower the laser power while maintaining adequate cutting performance.

- Increase Cutting Speed: A faster cutting speed reduces heat buildup.

- Use Pulse Cutting: Implement pulse cutting to minimize continuous heat input.

- Clamping: Use clamps or fixtures to secure the material and prevent warping.

Laser Power Recommendations for Various Materials

Selecting the right laser power is crucial for efficient cutting. Here’s a general guideline for different materials and thicknesses:

| Material | Thickness (mm) | Recommended Laser Power (W) | Cutting Speed (m/min) | Assist Gas |

|---|---|---|---|---|

| Mild Steel | 1-3 | 500-1000 | 10-20 | Oxygen |

| Mild Steel | 4-6 | 1000-2000 | 5-10 | Oxygen |

| Mild Steel | 8-12 | 3000-4000 | 2-5 | Oxygen |

| Stainless Steel | 1-3 | 1000-2000 | 6-12 | Nitrogen/Argon |

| Stainless Steel | 4-6 | 2000-3000 | 3-6 | Nitrogen/Argon |

| Stainless Steel | 8-10 | 4000-6000 | 1-3 | Nitrogen/Argon |

| Aluminum | 1-3 | 1000-2000 | 5-8 | Nitrogen/Argon |

| Aluminum | 4-6 | 3000-4000 | 3-5 | Nitrogen/Argon |

| Aluminum | 8-12 | 6000+ | 1-2 | Nitrogen/Argon |

Note: These values are approximate and may vary based on specific material grades, machine configurations, and desired cut quality.