language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Esperanto

Slovenski

Filipino

Suomi

Français

Maori

Shqiptare

Shqiptare

Georgian

Euskara

Euskara

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Zulu

Zulu

Latvian

Lithuanian

Luxembourgish

Latinus

Latinus

Macedonian

Малайская

Maltese

Монгол улс

Cymraeg

Cymraeg

ဗမာ

தமிழ்

தமிழ்

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Slovak

Slovak

Србија

Slovak

Slovak

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Afrikaans

Afrikaans

Việt Nam

-

-

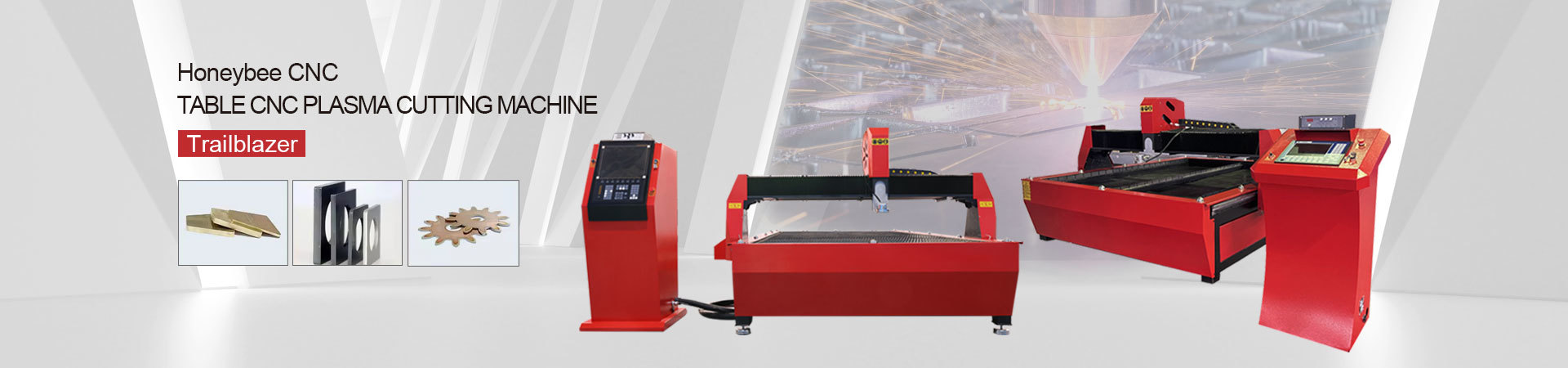

About Us

-

Service

-

News

News Center

Close type laser cutting machine

1.It is safer with a protective cover to prevent mechanical damage: it prevents splashes and debris, and protects the operator and surrounding personnel from harm; it provides all-round protection, and the laser processing area is shielded from multiple angles, effectively preventing personnel from approaching the danger zone from any direction;

2.The exchange table has high working efficiency, and it can pick up and load materials while cutting, saving labor costs: by equipping with an automated exchange system, the exchange of work can be completed faster without excessive human interference; uninterrupted continuous processing is achieved to maximize equipment utilization; loading and unloading operations are carried out simultaneously during equipment processing, realizing simultaneous processing and loading and unloading

3.The dust removal effect is better and more environmentally friendly: the closed space limits the dust diffusion range and is easier to centrally handle; the closed large enclosure can block external airflow interference, forming a closed space inside, which can achieve better results

4.Aesthetics: Integrate all parts of the laser equipment into a complete shell to form a unified and coordinated overall appearance; the use of high-quality materials and surface treatment enhances the aesthetics

5.With enclosure to reduce harm to human eyes: large enclosure design prevents sparks from flying during cutting, reduces fire and other hazards, covers the sheet metal shell in all directions, reduces cutting floating and dust flying, and the cutting process is environmentally friendly, smoke-free and pollution-free; dark acrylic windows allow the indoor cutting process to be clearly seen, and can also prevent light sources from causing damage to glasses

6.Surrounded by less noise: The safety cover helps to isolate noise and smoke, improving the working environment

7.Optional grating guardrail is safer: real-time monitoring and early warning to remind operators to pay attention and avoid accidents; multi-area protection, multi-angle protection at the same time; adapt to complex environments; visual instructions to clearly understand the working status and safety situation

Dalian Honeybee CNC Equipment Co., Ltd.

Tel: +86-411-82837868

Email:sale@honeybeecnc.cn

Mobilephone/whatsapp: +86-15940816686

Site:www.honeybeecnc.com

www.honeybee-cnc.com