Products

Metal Pipe and Sheet CNC Plasma Cutting Machine

1500X3000mm plate cut; 50-300mm round pipe cut; 0-25mm steel plate cutting

Working Size:

Cut Thick:

1500x3000mm

0-25mm steel

Keywords:

Classification:

Plasma/Oxy-fuel Cutting

Pipe CNC Cutting Machine

Whatsapp:+8615940816686

Related Downloads

- Product Description

- parameter

-

We have customers from all over the world and have been cooperating for over 10 years. Thank you for choosing Honeybee CNC.

We will continue to improve product quality and after-sales service.

Building trust starts with communication

Whether you want to use it yourself or as a local agent, we are your most reliable partner.

Please leave your contact information so that we can serve you better.

This CNC machine for sheet metal cutting table-Trailblazer adopts integral structure, making installation easier and more reliable. This cutting table adopts double-side driving to make the torch does longitudinal movement followed by straight tracks. The light design of the crossbeam has good rigidity, light self-weight, and good stability of movement. The machine is equipped with water tank type dust-removing equipment, in order to achieve environmental protection requirements; a smoking type dust-removing equipment also can be applied according to the customer’s needs. The plasma table is suitable for high-speed cutting thin sheet made of stainless steel, aluminium sheet and nonferrous metals etc. Additionally, it also has able to cutting thick plate. The machine is widely applied for sheet-metal working, auto parts, Wind turbines, and steel mould industries, etc .

Features:

No need make cutting table at customer end.

No need assembly at customer side and save customer time and money.

Parameters:

Technical Parameters: Cut Size 1500*3000mm,1500x4000mm,2000x4000mm Drive system Japan AC servo motor and Gear & step motor for optional Cutting Thickness 0.5-25mm mild steel by plasma ;6-50mm mild steel by oxy-fuel cutting

50-300mm round pipe cutting(Straight cut)

Cutting Speed 0-10m/min Moving Speed 0-10m/min Power 1KW+Plasma power Input Voltage 3 phase 380V,or 2 phase 220V Power Frequency 50Hz,60Hz Files Transfer USB Interface Plasma Supply Option Untouched Arc Striking,Hypertherm,Victor, China Taiwan plasma generator option

CNC bed

The Heavy Duty strucutre ensures the long-term operation is non-deformation-free, and the operation is vibration-free to ensure accuracy. At the same time the workbench can store water.

Controller:

Independ controller cabinet,strong anti-jamming ability, Easy operation

17 inch display easy to operate.

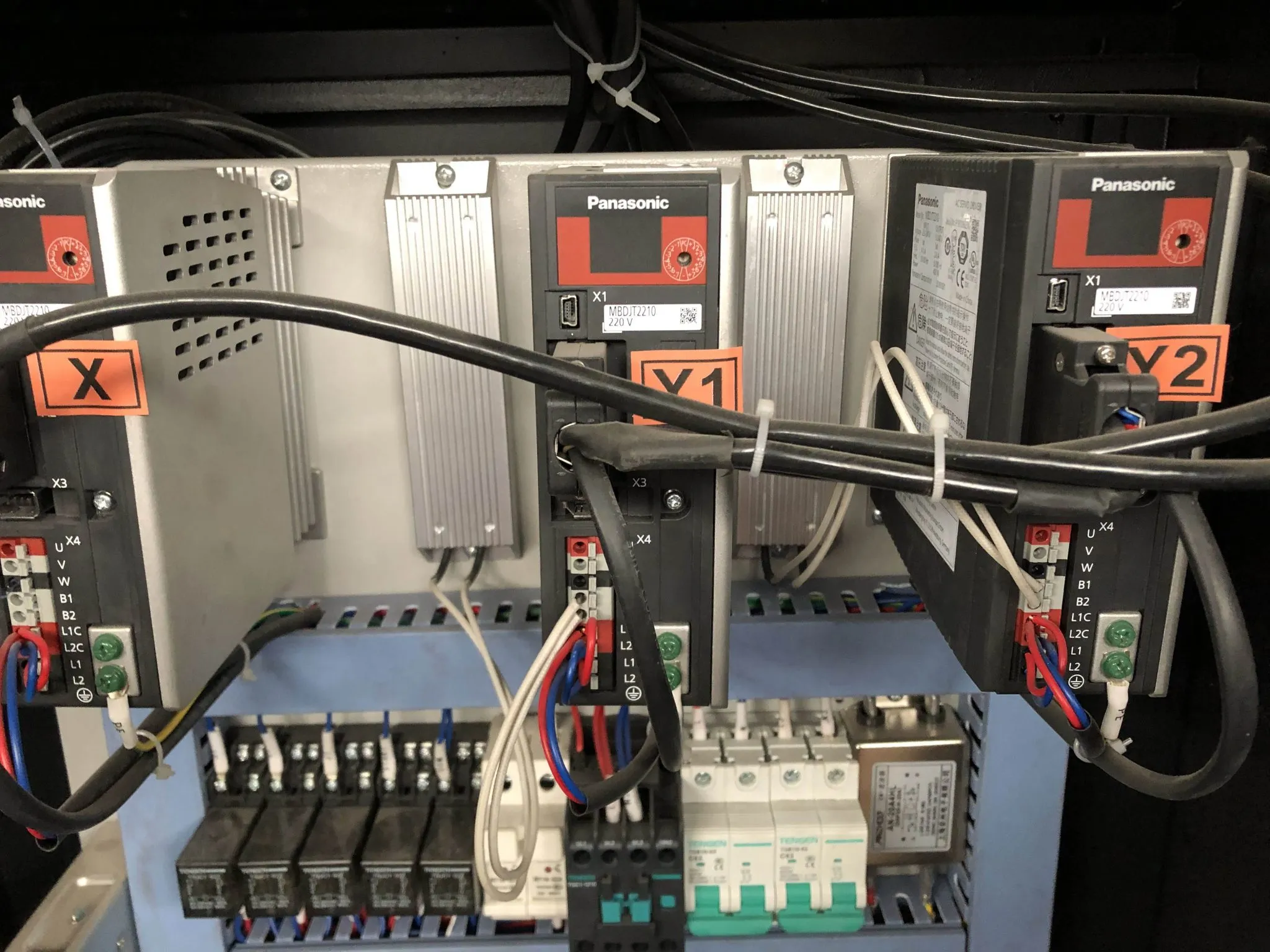

Drive unit

Panasonic drive unit to make sure the high running precesion and long life use.

Torch Height controller

Prevent the cutting torch from being damaged by the parts cut or uneven steel plate and stop the machine immediately to avoid loss

Both plasma and flame cut, Anti-collision

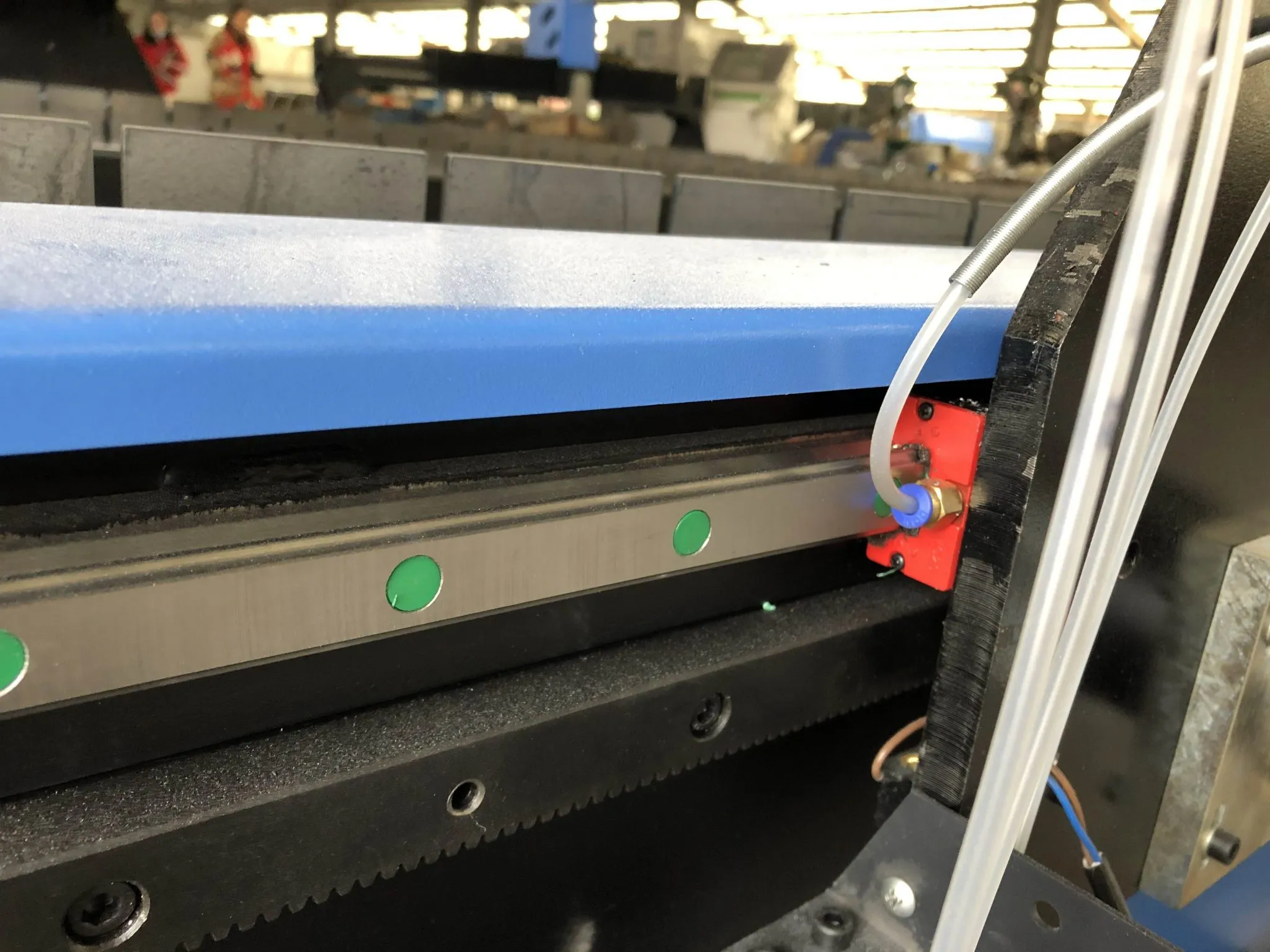

Taiwan Brand Linear Rail

Taiwan or Japan Liner rail to make sure the high cutting precesion

Key words:

Key words:- 1530 plasma cut table

- 5x10 plasma table

- plate pipe plasma cutting machine

- plasma cutting table

- plasma cutting aluminum

- cnc plasma cutter machine

- plasma cutting machine cnc

- cnc plasma cutter

-

-

Features

- 介绍

-

Previous

CNC Plasma cutting machine

Get a Quote