News Center

Application of Pipe Laser Cutting Machine in Industry

Fully automatic pneumatic chuck

Intelligent pipe cutting system

Cutting square tubes, round tubes, elliptical tubes, U tubes

Capable of stable clamping processing for heavy-duty pipes

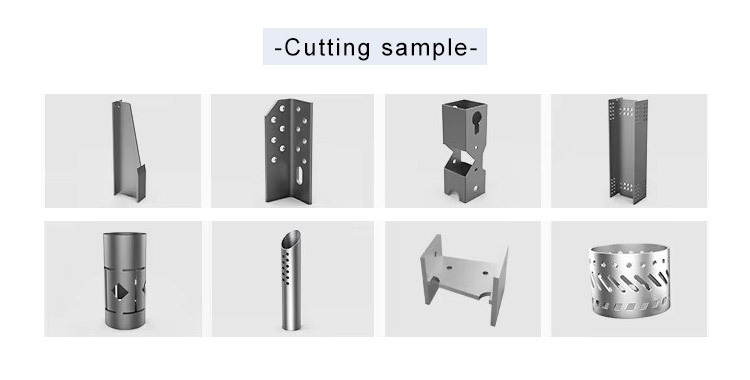

Can cut profiles such as round pipes, rectangular pipes, and special-shaped pipes

Key Industrial Applications of Pipe Laser Cutting Machines

Key Industrial Applications of Pipe Laser Cutting Machines

1. Metal Fabrication Industry

✅ Automotive Manufacturing

- Exhaust systems: Precise cutting of complex-shaped exhaust pipes and muffler components

- Chassis & structural parts: Frame tubes, crash beams, and reinforcement structures

- EV battery trays: High-precision cutting of aluminum/stainless steel tubes

✅ Aerospace

- Fuel & hydraulic tubes: High-accuracy cutting of titanium/alloy pipes

- Lightweight structural components: Complex profiling of aircraft-grade aluminum tubes

✅ Rail Transportation

- Train/Subway body frames: Angled cuts and welding grooves for square/round tubes

- Seat frames & luggage racks: Custom stainless steel/aluminum tube designs

2. Machinery & Heavy Equipment

✅ Construction Machinery

- Excavator/Crane booms: 3D cutting of high-strength steel pipes (no secondary machining)

- Hydraulic tubing: Precision end-facing of pressure-resistant pipes

✅ Agricultural Machinery

- Harvester conveyor frames: Hole-cutting and bevelling of wear-resistant tubes

- Irrigation systems: Mass production of standardized pipe fittings

3. Furniture & Architectural Design

✅ Metal Furniture

- Chair/Table frames: Artistic curves and patterns in stainless steel/carbon steel tubes

- Display racks: Precision-cut interlocking tube connectors

✅ Building Decoration

- Stair railings: Complex curved stainless steel tube cuts

- Curtain wall frames: Rapid drilling and slotting of aluminum profiles

4. Energy & Petrochemical

✅ Oil & Gas

- Pipeline systems: Bevel cutting for large-diameter welded pipes

- Downhole tools: Corrosion-resistant alloy tube machining

✅ Renewable Energy (Solar/Wind)

- Solar mounting structures: High-speed batch cutting of aluminum tubes

- Wind tower components: Thick-walled steel tube profiling

5. Medical & Fitness Equipment

✅ Medical Devices

- Hospital bed/wheelchair frames: Burr-free cutting of sterilizable stainless steel tubes

- Orthopedic implant molds: Micro-cutting of titanium tubes

✅ Fitness Equipment

- Dumbbell bars: Straight/threaded cuts for high-load steel pipes

- Treadmill frames: Integrated shaping of custom tube profiles

⚙️ Core Advantages of Laser Tube Cutting

Advantage | vs. Traditional Methods |

High Precision | ±0.1mm tolerance (outperforms plasma/flame cutting) |

Contactless Cutting | No mechanical deformation (ideal for thin-walled tubes) |

Complex Shapes | Cuts bevels, 3D curves, and special holes (e.g., clover shapes) |

Automation | 24/7 production with robotic loaders |

Eco-Friendly | No dust pollution; 70% less energy consumption |

📌 Industry Case Studies

Automotive Exhaust Manifolds

- Requirement: Multi-angle branching with weld-ready edges

- Solution: Single-step laser cutting eliminates milling

Decorative Metal Railings

- Need: Ornamental stainless steel perforations

- Result: Laser-cut patterns bent into final shapes

EV Battery Enclosures

- Challenge: Lightweight yet strong aluminum tubes

- Outcome: 20% weight reduction via laser cutting + welding

🚀 Future Trends

- Smart Factory Integration: MES-connected automated tube processing

- High-Power Fiber Lasers: 50% faster cutting for thick-wall tubes (e.g., 25mm carbon steel)

- AI Quality Control: Real-time cut monitoring with auto-adjustments