News Center

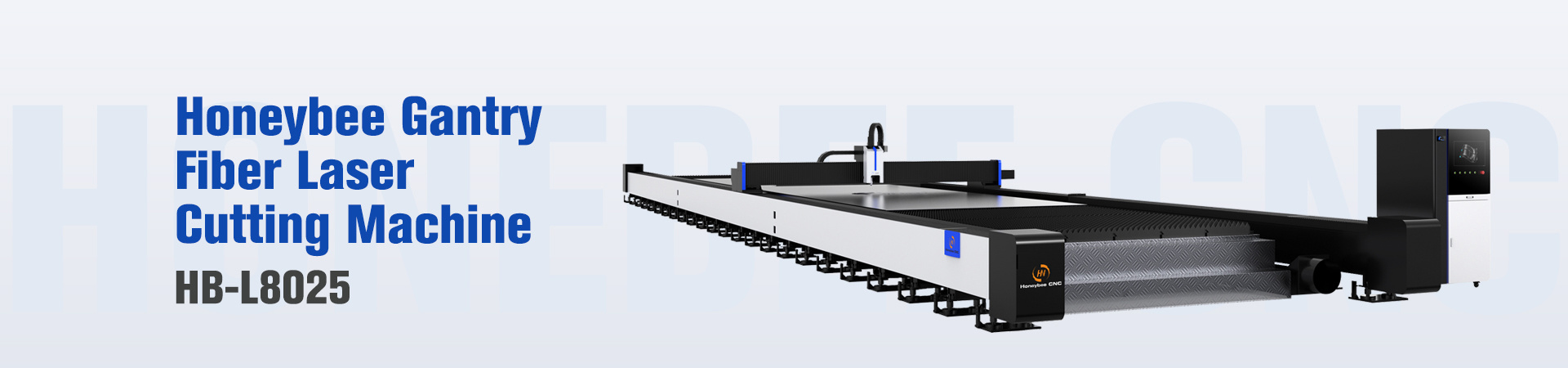

Achieving Superior Cutting Results: Gantry Fiber Laser Cutter

---

# Introduction

In today's fast-paced industrial landscape, precision cutting is essential for achieving optimal results in various applications. The Gantry Fiber Laser Cutter is a cutting-edge piece of equipment that combines advanced technology with efficiency to deliver superior cutting results. In this article, we will delve into the features and benefits of the Gantry Fiber Laser Cutter and how it can revolutionize your cutting processes.

# What is a Gantry Fiber Laser Cutter?

The Gantry Fiber Laser Cutter is a high-tech cutting machine that utilizes fiber laser technology to achieve precise and efficient cutting of various materials. With its gantry structure, the machine offers stability and accuracy, making it ideal for industrial applications that require intricate cutting processes. The fiber laser beam produced by the machine is capable of cutting through a wide range of materials with ease, including metals, plastics, and composites.

## Key Features of the Gantry Fiber Laser Cutter

- Precision cutting with high accuracy

- Fast cutting speed for increased productivity

- Low maintenance requirements for cost-effective operation

- Versatile cutting capabilities for a wide range of materials

- User-friendly interface for easy operation

# Benefits of Using a Gantry Fiber Laser Cutter

When it comes to achieving superior cutting results, the Gantry Fiber Laser Cutter offers numerous benefits that set it apart from traditional cutting methods. Some of the key advantages of using this cutting machine include:

- Enhanced precision and accuracy in cutting processes

- Increased efficiency and productivity due to fast cutting speeds

- Reduced material waste and improved cost-effectiveness

- Versatile cutting capabilities for diverse material types

- Improved safety features for operator protection

# How to Achieve Superior Cutting Results with the Gantry Fiber Laser Cutter

To maximize the performance of the Gantry Fiber Laser Cutter and achieve superior cutting results, it is essential to follow some best practices:

1. Proper machine calibration and maintenance to ensure optimal cutting performance.

2. Regular inspection of cutting parameters to adjust settings for different materials.

3. Utilization of advanced software features for customized cutting solutions.

4. Operator training and certification to operate the machine safely and efficiently.

5. Quality control measures to ensure consistency in cutting results.

# FAQs

## Q: What materials can the Gantry Fiber Laser Cutter cut?

A: The Gantry Fiber Laser Cutter can cut a wide range of materials, including metals, plastics, and composites.

## Q: How fast is the cutting speed of the Gantry Fiber Laser Cutter?

A: The Gantry Fiber Laser Cutter offers fast cutting speeds for increased productivity.

## Q: Is the Gantry Fiber Laser Cutter easy to operate?

A: Yes, the Gantry Fiber Laser Cutter features a user-friendly interface for easy operation.

## Q: How does the Gantry Fiber Laser Cutter achieve precision cutting?

A: The Gantry Fiber Laser Cutter utilizes advanced fiber laser technology for precise and accurate cutting.

## Q: Are there any safety features in place for operators using the Gantry Fiber Laser Cutter?

A: Yes, the Gantry Fiber Laser Cutter is equipped with safety features to protect operators during cutting processes.

# Conclusion

In conclusion, the Gantry Fiber Laser Cutter is a cutting-edge solution for achieving superior cutting results in industrial equipment and components. With its advanced technology, precision cutting capabilities, and efficiency, this cutting machine can revolutionize your cutting processes and take your operations to the next level. Invest in the Gantry Fiber Laser Cutter today and experience the difference in your cutting results.

# Introduction

In today's fast-paced industrial landscape, precision cutting is essential for achieving optimal results in various applications. The Gantry Fiber Laser Cutter is a cutting-edge piece of equipment that combines advanced technology with efficiency to deliver superior cutting results. In this article, we will delve into the features and benefits of the Gantry Fiber Laser Cutter and how it can revolutionize your cutting processes.

# What is a Gantry Fiber Laser Cutter?

The Gantry Fiber Laser Cutter is a high-tech cutting machine that utilizes fiber laser technology to achieve precise and efficient cutting of various materials. With its gantry structure, the machine offers stability and accuracy, making it ideal for industrial applications that require intricate cutting processes. The fiber laser beam produced by the machine is capable of cutting through a wide range of materials with ease, including metals, plastics, and composites.

## Key Features of the Gantry Fiber Laser Cutter

- Precision cutting with high accuracy

- Fast cutting speed for increased productivity

- Low maintenance requirements for cost-effective operation

- Versatile cutting capabilities for a wide range of materials

- User-friendly interface for easy operation

# Benefits of Using a Gantry Fiber Laser Cutter

When it comes to achieving superior cutting results, the Gantry Fiber Laser Cutter offers numerous benefits that set it apart from traditional cutting methods. Some of the key advantages of using this cutting machine include:

- Enhanced precision and accuracy in cutting processes

- Increased efficiency and productivity due to fast cutting speeds

- Reduced material waste and improved cost-effectiveness

- Versatile cutting capabilities for diverse material types

- Improved safety features for operator protection

# How to Achieve Superior Cutting Results with the Gantry Fiber Laser Cutter

To maximize the performance of the Gantry Fiber Laser Cutter and achieve superior cutting results, it is essential to follow some best practices:

1. Proper machine calibration and maintenance to ensure optimal cutting performance.

2. Regular inspection of cutting parameters to adjust settings for different materials.

3. Utilization of advanced software features for customized cutting solutions.

4. Operator training and certification to operate the machine safely and efficiently.

5. Quality control measures to ensure consistency in cutting results.

# FAQs

## Q: What materials can the Gantry Fiber Laser Cutter cut?

A: The Gantry Fiber Laser Cutter can cut a wide range of materials, including metals, plastics, and composites.

## Q: How fast is the cutting speed of the Gantry Fiber Laser Cutter?

A: The Gantry Fiber Laser Cutter offers fast cutting speeds for increased productivity.

## Q: Is the Gantry Fiber Laser Cutter easy to operate?

A: Yes, the Gantry Fiber Laser Cutter features a user-friendly interface for easy operation.

## Q: How does the Gantry Fiber Laser Cutter achieve precision cutting?

A: The Gantry Fiber Laser Cutter utilizes advanced fiber laser technology for precise and accurate cutting.

## Q: Are there any safety features in place for operators using the Gantry Fiber Laser Cutter?

A: Yes, the Gantry Fiber Laser Cutter is equipped with safety features to protect operators during cutting processes.

# Conclusion

In conclusion, the Gantry Fiber Laser Cutter is a cutting-edge solution for achieving superior cutting results in industrial equipment and components. With its advanced technology, precision cutting capabilities, and efficiency, this cutting machine can revolutionize your cutting processes and take your operations to the next level. Invest in the Gantry Fiber Laser Cutter today and experience the difference in your cutting results.